Located in the heart of Minneapolis, Minnesota, at the busy off ramp from Interstate 35 and the terminus of Highway 65, a few blocks away from US Bank Stadium and the downtown financial district, is the historic Francis Drake Hotel. Built in 1926, the Drake Hotel was initially constructed as a luxury hotel; it now serves as a temporary residence for homeless families and individuals.

Despite its age, neither the hotel nor its underground infrastructure had ever been updated. In early summer 2017, a sink hole was discovered below 5th Avenue South, caused by a failure in the hotel’s side sewer and its connection to the mainline.

This sink hole presented a major problem for the traveling public as thousands of cars rely on this corridor daily. To make matters worse, a nearby bypass tunnel, which allows traffic to avoid the downtown area, had also been partially closed for unrelated repairs and maintenance. This forced even more commuters onto 5th Avenue South, the site of the sewer failure. Moreover, the cost for a traditional open-cut rehabilitation method was estimated to be approximately $45,000 for this single repair and take several days to complete, disrupting nearby businesses. Decision-makers from the City of Minneapolis determined that an extended closure of 5th Avenue South 5th for an open-cut excavation to replace the side sewer and mainline connection would not be possible.

In situations like this, sewer agencies tend to take a keen interest in options available through the use of trenchless technologies, which is the use of methods and equipment to renew or replace existing underground infrastructure with minimal disruption to surface traffic, business or property. In this case, the City of Minneapolis was no exception, and city sewer maintenance supervisor Sean Oberg, who worked as a facilitator with the Drake Hotel, reached out to LMK Technologies regional sales manager Pete Dannenberg.

Based in Ottawa, Illinois, LMK Technologies has been offering trenchless cured in place-pipe (CIPP) lining solutions since 1993 and was known to Oberg as an innovative problem-solver. Oberg explained that the mainline pipe was a unique oval shape, and 18 in. in diameter, making it larger than average, previously repaired with a CIPP liner. The sewer line from the Drake to the main was a more typical 6-in. diameter pipe with a “tee” style connection to the mainline. Confronted with this unique challenge, LMK’s technical team went to work, crafting a solution to repair the problem using a custom designed T-Liner. They decided that LMK’s T-Liner would be the best solution to meet this need.

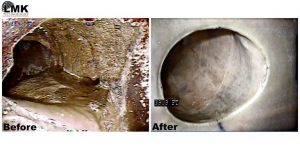

The T-Liner system is a one-piece main-to-lateral CIPP connection liner. The liner is formed as a structural cylinder and renews 18 in. of the mainline at the main-to-lateral interface and extends up the lateral pipe simultaneously. The T-Liner can line a service lateral up to 150 ft from the main pipe in one installation. The system utilizes hydrophilic rubber gaskets, compliant with ASTM F3240, which swell after becoming moist, and form a seal between the host pipe and the new liner which therefore provides a watertight connection, eliminating groundwater infiltration and wastewater exfiltration. Because of these unique features, the T-Liner is compliant with ASTM F2561, which is the industry standard countless sewer agencies turn to when looking to simultaneously rehabilitate a sewer service lateral and its connection to the main using a single liner.

Trenchless installation of LMK Technologies’ T-Liner system would structurally renew the leaking pipes quickly and without shutting down streets and businesses, and it was much more cost-effective than digging. Most importantly, the Drake Hotel was able to stay open during the entire process. Dannenberg contacted Quam Construction, a Minneapolis contractor and LMK licensed contractor, for this project based on a past record of success working together on multiple projects since June 2015, when Quam first entered the field of trenchless lateral rehabilitation.

“Our relationship with LMK has been fantastic,” Quam vice president of trenchless pipe solutions Judd Stattine says. “Working with LMK has allowed us to diversify our labor, expand our tool box, and have more trenchless solutions in general.” Quam verified the pipe and its shape and size by accessing the manhole in the street, providing critical details LMK needed to design the T-Liner. LMK technical staff custom-designed and tested its trenchless solution, while the Quam team worked out the on-site details on how to complete the installation while keeping traffic moving and the Drake Hotel in operation. To lessen its impact, the project was split into two different phases, timed to be undertaken one week apart.

The project first required a sewer lateral cleanout outside the hotel. LMK’s ASTM F3097 compliant trenchless VAC-A-TEE system was the chosen solution because it would enable installation of a cleanout access point with minimal equipment footprint and minimal disruption to the surface. Phase 1 would be to site and install the VAC-A-TEE. Phase 2 would be to repair the lateral service connection utilizing the cleanout with a T-Liner, which would extend 8 ft up the service lateral pipe to be installed from the sewer main.

Working closely with the City, Quam closed the street parking lane, creating one single lane of traffic, on the June evening chosen for the execution of the Phase 1 cleanout installation. After the cleanout was installed, they backfilled the area with sand and a layer of black dirt to restore the cleanout site to its original condition. The process, which took only three hours to complete, began at 9 p.m. With minimal disruption, Phase 1 was successfully concluded.

Phase 2 began exactly one week later. Again at 9 p.m., Quam closed three lanes of the road and used the parking lane so traffic could flow between 10th and 9th streets, as well as 5th Avenue South. The crew used a specialized single-access self-propelled robot to clean the pipe and connection, removing all obstructions. It then fully saturated the T-liner with resin, loaded it into the liner’s launching device, and pulled it 215 ft into the mainline pipe to the repair location. Using the VAC-A-TEE cleanout installation, the crew watched the positioning of the liner during the inversion process in real time with a CCTV camera.

Once the liner was positioned, air pressure was used to inflate the mainline portion against the sidewall of the 18-in. diameter oval mainline pipe and the lateral liner was then inverted up the service pipe, also using air pressure. Once the liner was fully inverted, Quam used steam curing methods, which took 75 minutes. Once cured, Quam removed the bladder and launcher assembly from the mainline pipe. After a CCTV inspection, the crew cleaned up and removed its traffic control equipment, restoring full access to the roadway by midnight. The City used compacted stone to fill the sink hole, finishing the repair with asphalt. Phase 2 also took only three hours, and the entire project cost $17,000, saving the Drake Hotel $28,000 — or just more than one third the cost vs. open-cut excavation.

“Overall, it’s accurate to say that the City is happy with the results,” says Katrina Kessler, director of surface water and sewers for the City of Minneapolis. “The minimally invasive solutions were ideal because the issue was in a very congested part of downtown Minneapolis where we strive to lessen traffic concerns and impacts to residents and the traveling public.” If the crew had used open-cut methods, it would have closed all the impacted roads during the two to three days required to complete the job.

Dannenberg notes that “being able to do this with trenchless technology — as the city advised — turned out to be a fantastic decision for all parties.”

LMK founder and president Larry Kiest Jr. agrees. “We are pleased with the results and ecstatic that the Drake Hotel was able to use trenchless CIPP rehabilitation methods. There is no challenge too big or too small for what we do. At LMK, we welcome challenges that require us to build unique solutions,’ he says.