LMK Technologies

sEWER LATERAL RENEWAL SYSTEMS

LMK Technologies has pioneered CIPP lateral renewal technology and has driven the industry forward with new products and technologies to facilitate sewer rehabilitation of sewers for 20 years.

Engineer

Specify ASTM Compliant CIPP Technologies for Long-Term Rehabilitation.

Utility Owner

Optimize your Infrastructure Rehabilitation Expenditures to Achieve Lasting Best Value Results.

Contractor

Diversify and Expand your Businesses with Effective Trenchless Rehabilitation Solutions.

Plumber/Drain Cleaner

Specify ASTM Compliant CIPP Technologies for Long-Term Rehabilitation.

Industry Leading

Products

extends up to 200ft up lateral

LMK’s T-Liner® is a one-piece homogenous main and lateral CIPP connection liner. Both the mainline and lateral sections are formed as a structural cylinder that renews 18-inches and 360-degrees of the mainline and extends up the lateral pipe as one continuous lining.

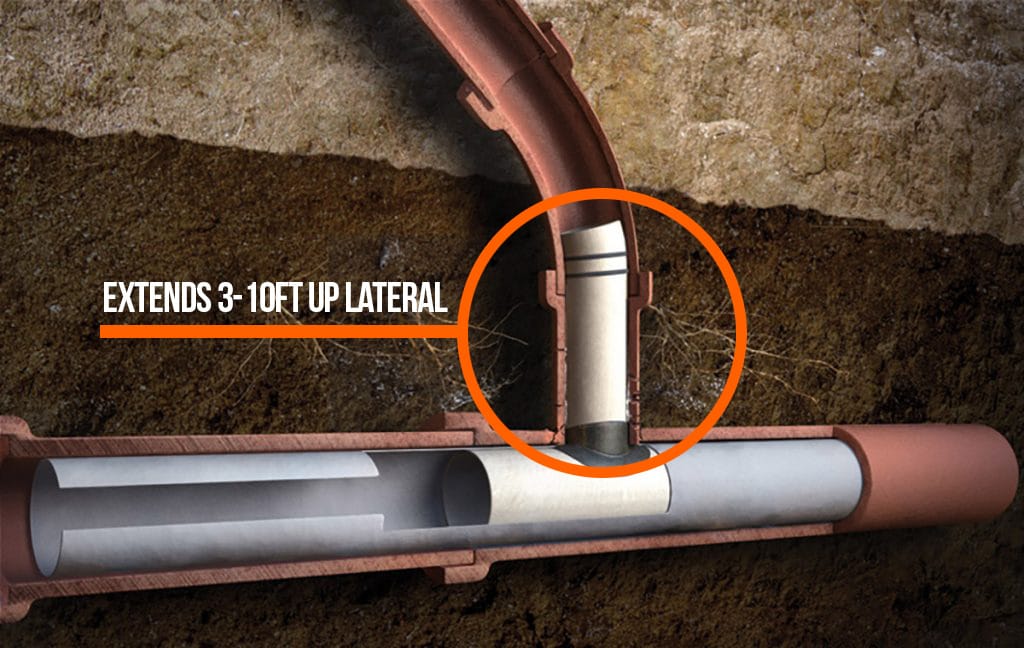

extends 3-10ft up lateral

The T-Liner® Shorty™ system is a one-piece, structural, stand-alone homogeneous main-to-lateral CIPP connection liner that extends 3-10 feet up into the lateral pipe.

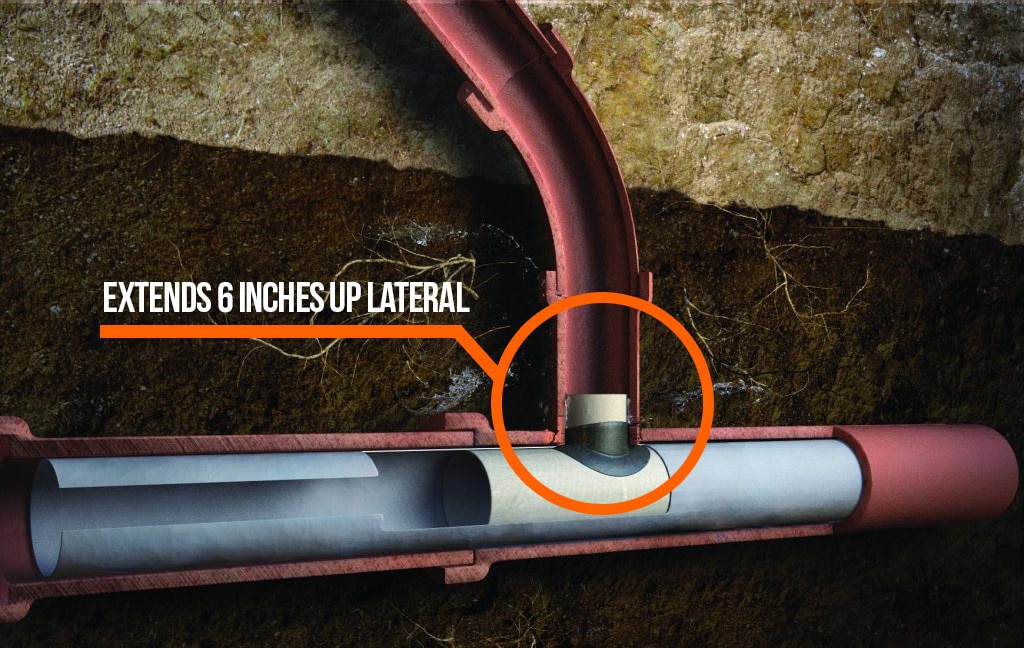

extends 6 inches up lateral

LMK’s Stubby™ incorporates a structural full-circle mainliner tube having proper wall thickness for each pipe diameter. This system extends 6″ up the sewer lateral.

Customized

Equipment

A Full-Service Trenchless Equipment Fabrication Shop

LMK’s fabrication department is capable of 3-D prototyping and machining on a 3-axis CNC machine as well as MIG, TIG, plasma cutting, and metal rolling. LMK also builds custom lining wet-out trailers and all support equipment necessary to efficiently and effectively rehabilitate lateral sewer pipe lines, main-to-lateral connections and manholes. With a specialization in custom tailoring trenchless lining equipment to the specific needs of the contractor/installer, LMK takes pride in its team of qualified and innovative individuals including a full-time Technology Team. We encourage you to learn more on how LMK can assist your company in designing the trenchless equipment you need by contacting info@lmktechnologies.com or by calling 815-433-1275 to schedule your personal tour of the LMK manufacturing and fabrication facilities.

LMK

News

WRT Customer Update

To our valued Customers, Over the course of the last 7 days, we at WRT and PLI, have become aware...

NASTT’S TRENCHLESS TODAY: In The Trenches By Andrew Farr

Amana Arayan LMK TECHNOLOGIES “IT’S AN INDUSTRY THAT MAKES A MONUMENTAL DIFFERENCE WHEN IT COMES TO INFRASTRUCTURE, THE ENVIRONMENT AND...

2020 Events

No-Dig Show Booth #701 April 5-9, 2020 Colorado Convention Center (Denver, CO) LEARN MORE CONEXPO-CON/AGG Booth #S62753 March 10-14, 2020...

Customized

Equipment

Trust LMK for All Your CPP Lining & Pipe Liner Equipment Needs

LMK Technologies is an industry leader for cured-in-place pipe (CIPP) products that support the rehabilitation efforts of underground systems. For nearly 30 years, LMK has been at the forefront of trenchless sewer repairs through the production of unique and innovative CIPP lining solutions. Our pipe liner equipment and products can be applied to both lateral and mainline restoration projects, as well as manhole pipe liners. You can even order a Picote Smart Cutter, ideal for lateral reinstatement of a CIPP liner. If you’re ready to see how our trenchless company can help your project, contact us today to learn more about our revolutionary products.