Mainline Sectional Repair

- Home

- /Mainline Sectional Repair

Key Features:

Mainline: Animated Inversion Process

ASTM F2599

Standard Practice for The Sectional Repair of Damaged Pipe By Means of An Inverted Cured-In-Place Liner

Significance and Use

Purchase the full version of this standard by visiting the ASTM website here. This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of sewer service laterals and its connection to the main through the use of a resin-impregnated tube installed within an existing sewer lateral. As for any practice, modifications may be required for specific job conditions.

1. Scope

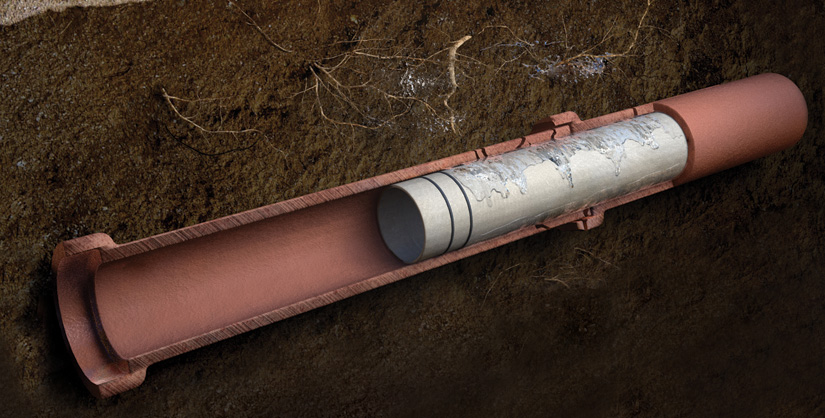

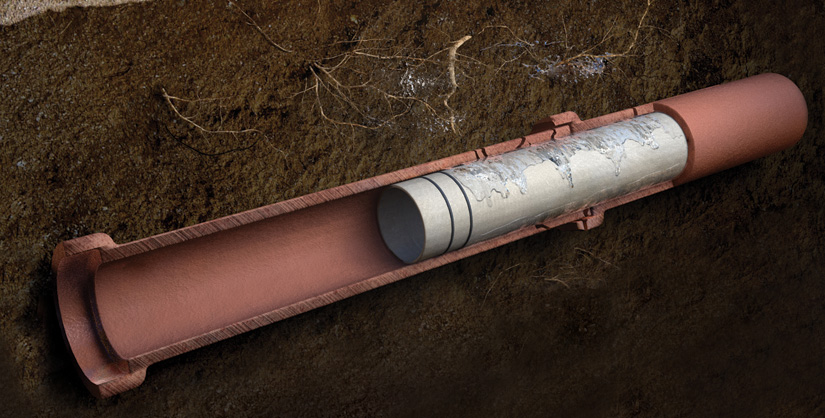

- This practice covers requirements and test methods for the sectional cured in place lining (SCIPL) repair of a pipe line (4 in, through 60 in. ) by the installation of a continuous resin-impregnated-textile tube into an existing pipe by means of air or water inversion and inflation. The tube is pressed against the host pipe by air or water pressure and held in place until the thermo set resins have cured. When cured, the sectional liner shall extend over a predetermined length of the host pipe as a continuous, one piece, tight fitting, corrosion resistant and verifiable non-leaking cured in place pipe.

- The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that provided for information only and are not considered standard.

- There is no similar or equivalent ISO Standard. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

2. Referenced Documents

- D1600 Terminology for Abbreviated Terms Relating to Plastics

- D3681 Test Method for Chemical Resistance of Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe in a Deflected Condition

- D5813 Specification for Cured-In-Place Thermosetting Resin Sewer Piping Systems

- D790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

- F1216 Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube

- F412 Terminology Relating to Plastic Piping Systems

NASSCO Guidelines

- RecommendedSpecifications for Sewer Collection System Rehabilitation.

Index Terms

Sectional cured in place lining; tube; sheet; vacuum impregnate; continuous; bladder; textile; felt; knit; resin; inversion; inflation; ambient cure; steam cure; launcher; liner/bladder assembly; ICS Number Code 23.040.99 (Other pipeline components)

DOI

10.1520/F2599-16

For a copy of the ASTM F2599-16 Standard please visit www.astm.org.

Mainline Sectional Inversion Submittal

– 30 day chemical resistance LMK Test Results 052308

– DMA TDS

– Flex Report_Item III_Task Ord#3_4-28-100001

– Installation Specification for CIP Sectional Lining

– LMK 656 CIPP Resin Spectrograph

– Microbac Testing D543 Chemical Regeants

– Proper Care of LMK 656 Thermoset Resin

– Tensile Strength Graph_Task Order 6-1_Rec_d 01-07-11_Test_d 01-11-11

– Tensile Strength Test Results_Task Order #6-1_Recved 01-07-11_Tested 01-11-11

Case Studies and Articles

Insignia Gasket Sealing Technology

The Myth, the Fact and the Legend: Insignia Hydrophilic Sealing System

Sahar Hasan, Applications Engineer and Kristina Kiest, Director of Marketing

Published in Trenchless International Magazine, October 2012

Gasket Sealing Technology: A Solution to Sealing Deficiencies in Cured in-Place Pipe Lining

Kristina Kiest and John Vose

Presented at NASTT No-Dig March 2012

T-Liner Main-To-Lateral Connection And Vac-A-Tee Cleanout

A Comprehensive Understanding of ASTM F3097-15 “Standard Practice for Installation of an Outside Sewer Service Cleanout through a Minimally Invasive Small Bore Vacuum Excavation”

Rick Gage and Amana Arayan

Presented at NASTT No-Dig March 2016

Sealing the Connection for Large Diameter Pipes, Trenchlessly

Mike Czipar and Amana Arayan

Presented at NASTT No-Dig March 2016

Rehabilitation of the Coral Gables Wastewater Collection System

Sahar Hasan, Mark Gulyas, and Jorge Acevedo

Presented at NASTT No-Dig April 2014

A Technique for Renewing a Section of Mainline Pipe while Simultaneously Renewing Multiple Service Lateral Pipes through the Use of Continuous CIPP

Larry Keist and Sahar Hasan

Presented at NASTT No-Dig 2012

Lining Laterals in Las Olas

Kristina Kiest

Published in Trenchless Technology Magazine, October 2010

A Comprehensive Understanding of ASTM F2561-06 “The Standard Practice for Rehabilitation of a Sewer Service Lateral and its Connection to the Main Using a One-Piece Main and Lateral Cured-in-Place Liner.”

Larry Kiest, Jr. and Rick Gage

Presented at NASTT No-Dig March/April 2009

Trenchless Technologies; Quicker, Cleaner, Greener and Cheaper Ways to Get the Job Done

Kristina Breese

Published in the Professional Engineer, Spring 2008

Multiple Technologies – Maximum Flow Reduction

Northcrest-Afton Sewer Rehabilitation Project, New Castle County, Delaware

James W. Shelton and Michael T. Harmer

Presented at Mediterranean No-Dig, September 2007

The Lateral Lining Market Has Arrived: Lateral Work is Being Completed in All Corners of the World with More on the Way

Joan Blythe

Published in Trenchless Technology Magazine, April 2007

Trenchless Rehab from the Engineer’s Perspective

James W. Shelton

Published in Trenchless Technology Magazine, October 2006

Prince William County Service Authority Project Case Study

Shaun Flannery and Larry Kiest, Jr.

Published 2005

Wisconsin Raises the Bar Utilizing T-Liner

Shaun Flannery

Published 2003

Fighting the Tide; Installing and Rehabilitating Sewers Using Trenchless Techniques; Boston Water & Sewer Commission

Irene McSweeney Woodfall, P.E. and Michael Oliveira

Conference Proceedings, NASST No-Dig 2000

A Case Study In Infiltration Reduction through Trenchless Technology

South Palos Township Sanitary District, Cook County, Illinois

Aaron E Fundich, P.E. and Larry W. Kiest, Jr.

Published March 1999

Lateral Lining

Local Ordinances Dictate Lateral Renewal Technologies

Larry Kiest and Rick Gage

Presented at NASTT No-Dig 2010

Portland BES Advances in Sewer Maintenance and Repairs by Operating Multiple CIPP Crews

Joe Dvorak and Larry Kiest, Jr.

Presented at NASTT No-Dig April 2007

Criteria for an Effective Lateral Renewal Project Utilizing Trenchless Technology

Larry Kiest

Presented at American Society of Civil Engineers (ASCE), New Pipeline Technologies, 2003

Lateral Thinking

Keith Gribbins

Published in Trenchless Technology Magazine, April 2002

Sectional Spot Repair

Steam Cured Large Diameter CIPP Sectional Liners Make Fast Repairs in Sensitive Environmental Areas

Joan Blythe

Published October 2012

Siphon Spot Repairs in Tampa

Larry Kiest, Jr.

Published October 2010

CIPP Sectional/Point Repairs; Critical Factors – Finally Explained

Shaun Flanery

Published May 2010

Lined Main Tap

Every Lateral in Dane County gets a new Connection Using the LMK Lined Main Tap

Kristina Kiest and Larry Kiest

Published February 2011

Manhole

The Most Cost Effective Method for Eliminating Inflow

Larry Kiest

Presented at American Society of Civil Engineers (ASCE), Pipelines, 2006

Research

The Inspector is the Gatekeeper to a Successful CIPP Installation

Larry Kiest, Gerry Muenchmeyer, and Amana Arayan

Presented at NASTT No-Dig 2015

Protocols for the Quantification of Water-Tightness of a Rehabilitated Main/Lateral Sewer Connection

Rick Gage

Presented at NASTT No-Dig March 2011

Making it Stick; Contractors repairing sewer laterals with CIPP linings need to consider multiple factors that affect the quality of the lateral-to-main connection

Larry Kiest, Jr.

Published at the Pumper & Cleaner Environmental Expo International, February 2006

Verifiable Non-Leaking Connection Where No Water Migrates

Larry Kiest and Shaun Flanery

Presented at NASTT No-Dig 2005

Testing Top Hat Liners and Robotic Systems for Repair of Lateral Connections

Dr. -Ing. Bert Bosseler and Dipl.-ing. Gunther Kaltenhauser

IKT – Institute for Underground Infrastructure, Published June 2004